![]() 2020-07-15 14:01:42

2020-07-15 14:01:42

01

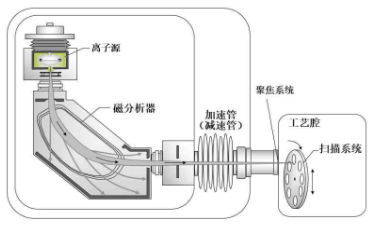

the ion implanter, together with the lithography machine, the etching machine and the coating machine, are called the four core equipment of semiconductor wafer manufacturing, and the development difficulty is second only to the lithography machine. the ion implanter is mainly composed of five parts: ion source, magnetic analyzer, accelerating tube or decelerating tube, focusing and scanning system, process chamber (target chamber and background processing system).

02

tungsten and molybdenum materials have the advantages of stable high temperature chemical properties, small thermal deformation and long service life, so the ion source components and consumables of ion implanters in the semiconductor industry are mostly made of tungsten and molybdenum materials. these devices include cathode shielding cylinders that emit electrons, arc chambers panel, etc. xiamen honglu has been deeply engaged in the field of tungsten and molybdenum processing for many years, and has mature processing technology and complete testing technology. after optimizing the traditional tungsten and molybdenum material process (including high purification, alloying treatment, sintering and densification, fine crystallization, secondary grain refinement, controlled rolling and controlled forging, etc.), the service life of traditional tungsten and molybdenum materials can be significantly improved. high temperature resistance and creep resistance.

03

performance characteristics of tungsten-molybdenum rod and tungsten-molybdenum plate for ion source of semiconductor ion implanter

relevant news